Articles

- Page Path

- HOME > Restor Dent Endod > Volume 42(3); 2017 > Article

- Research Article Effect of surface treatment on the mechanical properties of nickel-titanium files with a similar cross-section

-

Sang Won Kwak

, Joo Yeong Lee

, Joo Yeong Lee , Hye-Jin Goo

, Hye-Jin Goo , Hyeon-Cheol Kim

, Hyeon-Cheol Kim

-

2017;42(3):-223.

DOI: https://doi.org/10.5395/rde.2017.42.3.216

Published online: June 28, 2017

Department of Conservative Dentistry, Pusan National University School of Dentistry and Dental Research Institute, Yangsan, Korea.

- Correspondence to Hyeon-Cheol Kim, DDS, MS, PhD. Professor, Department of Conservative Dentistry, Pusan National University School of Dentistry, 20 Geumo-ro, Yangsan, Gyeongsangnam-do 50612, Korea. Tel: +82-55-360-5222, Fax: +82-55-360-5214, golddent@pusan.ac.kr

Copyright © 2017. The Korean Academy of Conservative Dentistry

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (https://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 1,325 Views

- 6 Download

- 3 Crossref

Abstract

-

Objectives The aim of this study was to compare the mechanical properties of various nickel-titanium (NiTi) files with similar tapers and cross-sectional areas depending on whether they were surface-treated.

-

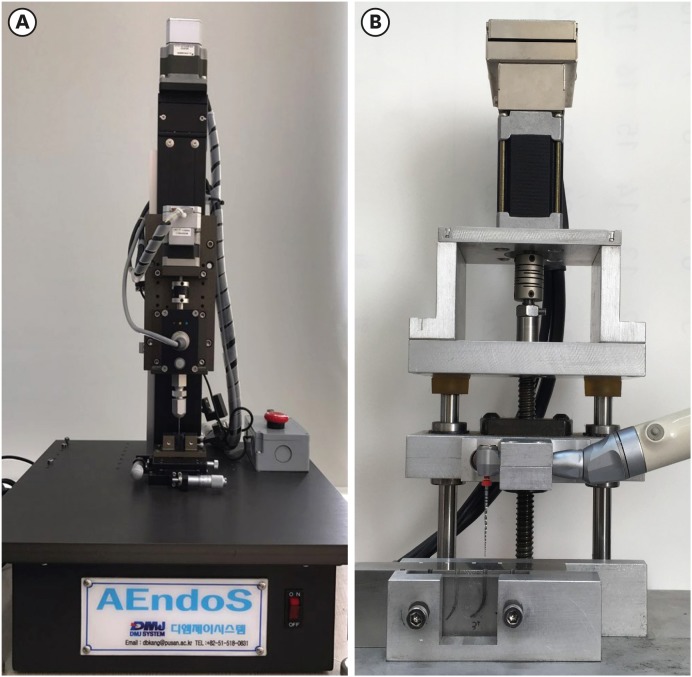

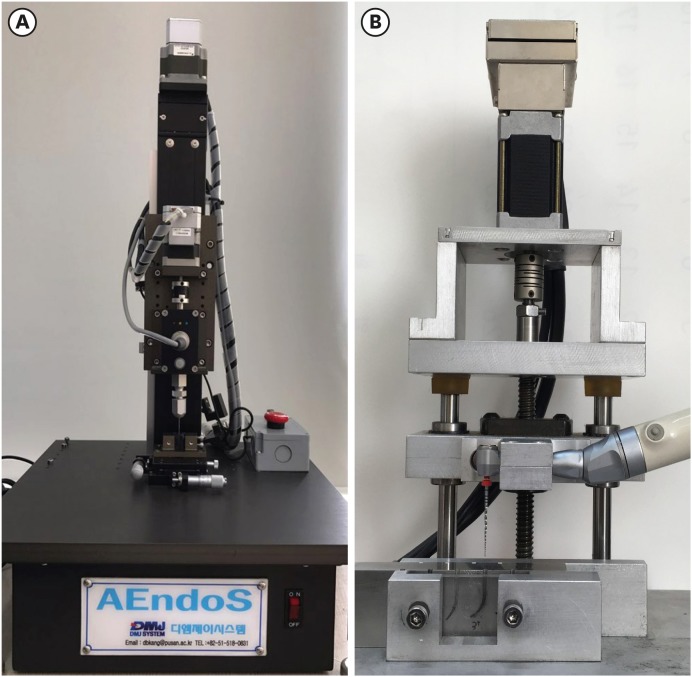

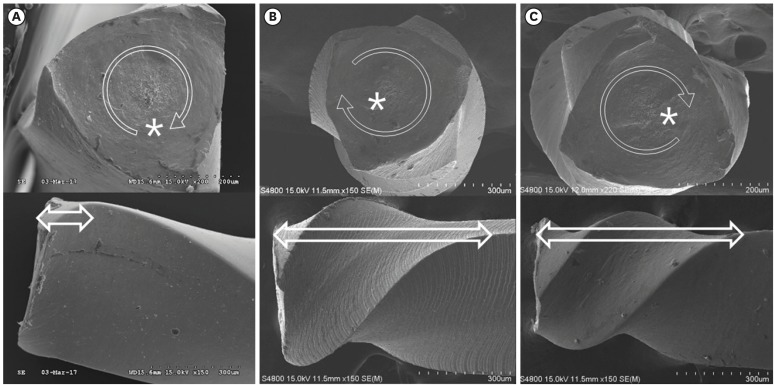

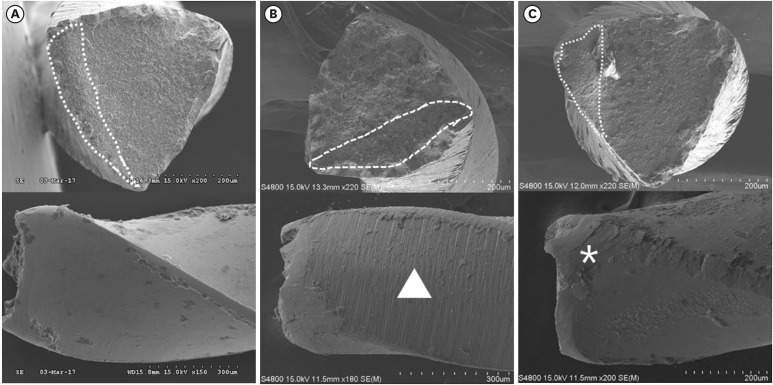

Materials and Methods Three NiTi file systems with a similar convex triangular cross-section and the same ISO #25 tip size were selected for this study: G6 (G6), ProTaper Universal (PTU), and Dia-PT (DPT). To test torsional resistance, 5 mm of the straightened file's tip was fixed between polycarbonate blocks (n = 15/group) and continuous clockwise rotation until fracture was conducted using a customized device. To evaluate cyclic fatigue resistance, files were rotated in an artificial curved canal until fracture in a dynamic mode (n = 15/group). The torsional data were analyzed using 1-way analysis of variance and the Tukey post-hoc comparison test, while the cyclic fatigue data were analyzed using the Mann-Whitney U test at a significance level of 95%.

-

Results PTU showed significantly greater toughness, followed by DPT and G6 (p < 0.05). G6 showed the lowest resistance in ultimate torsional strength, while it showed a higher fracture angle than the other files (p < 0.05). In the cyclic fatigue test, DPT showed a significantly higher number of cycles to failure than PTU or G6 (p < 0.05).

-

Conclusions Within the limitations of this study, it can be concluded that the torsional resistance of NiTi files was affected by the cross-sectional area, while the cyclic fatigue resistance of NiTi files was influenced by the surface treatment.

INTRODUCTION

MATERIALS AND METHODS

RESULTS

Torsional and cyclic fatigue resistance of the tested NiTi files

DISCUSSION

CONCLUSIONS

-

Funding: This work was supported by a 2-Year Research Grant of Pusan National University. The authors have no financial affiliations related to this study or its sponsors.

-

Conflict of Interest: No potential conflict of interest relevant to this article was reported.

-

Author Contributions:

Conceptualization: Kwak SW, Kim HC.

Data curation: Kwak SW, Lee JY, Goo HJ.

Formal analysis: Kwak SW, Kim HC.

Funding acquisition: Kwak SW.

Investigation: Kim HC.

Methodology: Goo HJ, Kim HC.

Project administration: Kwak SW, Kim HC.

Resources: Kwak SW, Lee JY.

Software: Kwak SW, Goo HJ.

Supervision: Kim HC.

Validation: Kwak SW, Kim HC.

Visualization: Kwak SW, Kim HC.

Writing - original draft: Kwak SW, Lee JY, Goo HJ.

Writing - review & editing: Kim HC.

- 1. Schäfer E, Schulz-Bongert U, Tulus G. Comparison of hand stainless steel and nickel titanium rotary instrumentation: a clinical study. J Endod 2004;30:432-435.ArticlePubMed

- 2. Peters OA. Current challenges and concepts in the preparation of root canal systems: a review. J Endod 2004;30:559-567.ArticlePubMed

- 3. Cheung GS, Liu CS. A retrospective study of endodontic treatment outcome between nickel-titanium rotary and stainless steel hand filing techniques. J Endod 2009;35:938-943.ArticlePubMed

- 4. Sonntag D, Guntermann A, Kim SK, Stachniss V. Root canal shaping with manual stainless steel files and rotary Ni-Ti files performed by students. Int Endod J 2003;36:246-255.ArticlePubMedPDF

- 5. Glossen CR, Haller RH, Dove SB, del Rio CE. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments. J Endod 1995;21:146-151.ArticlePubMed

- 6. Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod 2000;26:161-165.ArticlePubMed

- 7. Alapati SB, Brantley WA, Svec TA, Powers JM, Nusstein JM, Daehn GS. SEM observations of nickel-titanium rotary endodontic instruments that fractured during clinical use. J Endod 2005;31:40-43.ArticlePubMed

- 8. Cho OI, Versluis A, Cheung GS, Ha JH, Hur B, Kim HC. Cyclic fatigue resistance tests of nickel-titanium rotary files using simulated canal and weight loading conditions. Restor Dent Endod 2013;38:31-35.ArticlePubMedPMC

- 9. Cheung GS. Instrument fracture: mechanisms, removal of fragments, and clinical outcomes. Endod Topics 2007;16:1-26.Article

- 10. Tsujimoto M, Irifune Y, Tsujimoto Y, Yamada S, Watanabe I, Hayashi Y. Comparison of conventional and new-generation nickel-titanium files in regard to their physical properties. J Endod 2014;40:1824-1829.ArticlePubMed

- 11. Kim HC, Kim HJ, Lee CJ, Kim BM, Park JK, Versluis A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int Endod J 2009;42:593-602.ArticlePubMed

- 12. Kwak SW, Ha JH, Lee CJ, El Abed R, Abu-Tahun IH, Kim HC. Effects of pitch length and heat treatment on the mechanical properties of the glide path preparation instruments. J Endod 2016;42:788-792.ArticlePubMed

- 13. Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod 2013;39:163-172.ArticlePubMed

- 14. Kuhn G, Tavernier B, Jordan L. Influence of structure on nickel-titanium endodontic instruments failure. J Endod 2001;27:516-520.ArticlePubMed

- 15. Yum J, Cheung GS, Park JK, Hur B, Kim HC. Torsional strength and toughness of nickel-titanium rotary files. J Endod 2011;37:382-386.ArticlePubMed

- 16. Schneider SW. A comparison of canal preparations in straight and curved root canals. Oral Surg Oral Med Oral Pathol 1971;32:271-275.ArticlePubMed

- 17. Pruett JP, Clement DJ, Carnes DL Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod 1997;23:77-85.ArticlePubMed

- 18. Panitvisai P, Parunnit P, Sathorn C, Messer HH. Impact of a retained instrument on treatment outcome: a systematic review and meta-analysis. J Endod 2010;36:775-780.ArticlePubMed

- 19. McGuigan MB, Louca C, Duncan HF. The impact of fractured endodontic instruments on treatment outcome. Br Dent J 2013;214:285-289.ArticlePubMedPDF

- 20. Xu X, Eng M, Zheng Y, Eng D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J Endod 2006;32:372-375.ArticlePubMed

- 21. Park SY, Cheung GS, Yum J, Hur B, Park JK, Kim HC. Dynamic torsional resistance of nickel-titanium rotary instruments. J Endod 2010;36:1200-1204.ArticlePubMed

- 22. Wycoff RC, Berzins DW. An in vitro comparison of torsional stress properties of three different rotary nickel-titanium files with a similar cross-sectional design. J Endod 2012;38:1118-1120.ArticlePubMed

- 23. Baek SH, Lee CJ, Versluis A, Kim BM, Lee W, Kim HC. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J Endod 2011;37:1283-1286.ArticlePubMed

- 24. Yao JH, Schwartz SA, Beeson TJ. Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model. J Endod 2006;32:55-57.ArticlePubMed

- 25. Li UM, Lee BS, Shih CT, Lan WH, Lin CP. Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests. J Endod 2002;28:448-451.ArticlePubMed

- 26. Ray JJ, Kirkpatrick TC, Rutledge RE. Cyclic fatigue of EndoSequence and K3 rotary files in a dynamic model. J Endod 2007;33:1469-1472.ArticlePubMed

- 27. Cheung GS, Shen Y, Darvell BW. Does electropolishing improve the low-cycle fatigue behavior of a nickel-titanium rotary instrument in hypochlorite? J Endod 2007;33:1217-1221.ArticlePubMed

- 28. Kim HC, Yum J, Hur B, Cheung GS. Cyclic fatigue and fracture characteristics of ground and twisted nickel-titanium rotary files. J Endod 2010;36:147-152.ArticlePubMed

- 29. Kim BH, Ha JH, Lee WC, Kwak SW, Kim HC. Effect from surface treatment of nickel-titanium rotary files on the fracture resistance. Scanning 2015;37:82-87.ArticlePubMed

- 30. Anderson ME, Price JW, Parashos P. Fracture resistance of electropolished rotary nickel-titanium endodontic instruments. J Endod 2007;33:1212-1216.ArticlePubMed

REFERENCES

Tables & Figures

REFERENCES

Citations

- FARKLI YAPISAL ÖZELLİKTEKİ NİKEL-TİTANYUM KÖK KANAL EĞELERİNİN SODYUM HİPOKLORİT VE SERUM FİZYOLOJİK ÇÖZELTİLERİNDEKİ DÖNGÜSEL YORGUNLUK DİRENÇLERİNİN KARŞILAŞTİRİLMASI

Abdulkadir ÖZŞAHİN, Meltem DARTAR ÖZTAN, Emine ODABAŞI TEZER

Atatürk Üniversitesi Diş Hekimliği Fakültesi Dergisi.2021; : 1. CrossRef - Heat Treatment and Surface Treatment of Nickel–Titanium Endodontic Instruments

Sang Won Kwak, Ya Shen, He Liu, Zhejun Wang, Hyeon-Cheol Kim, Markus Haapasalo

Frontiers in Dental Medicine.2021;[Epub] CrossRef - Torsional Resistance of Two New Heat Treated Nickel Titanium Rotary Instruments: An in Vitro Evaluation

Gianluca Gambarini, Gabriele Miccoli, Dario Di Nardo, Andrea Del Giudice, Alessandro Mazzoni, Marco Seracchiani, Luca Testarelli

Pesquisa Brasileira em Odontopediatria e Clínica Integrada.2020;[Epub] CrossRef

Figure 1

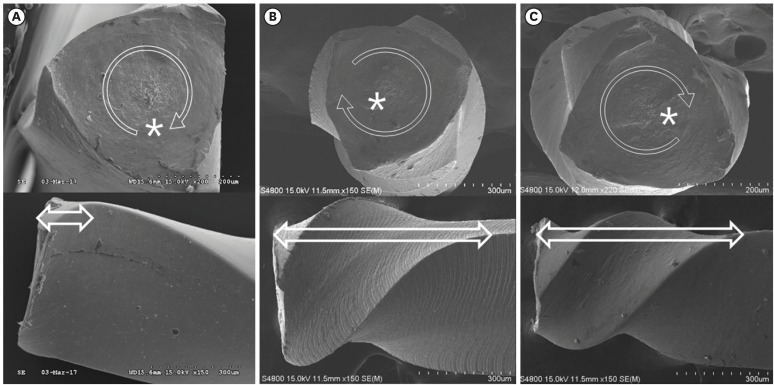

Figure 2

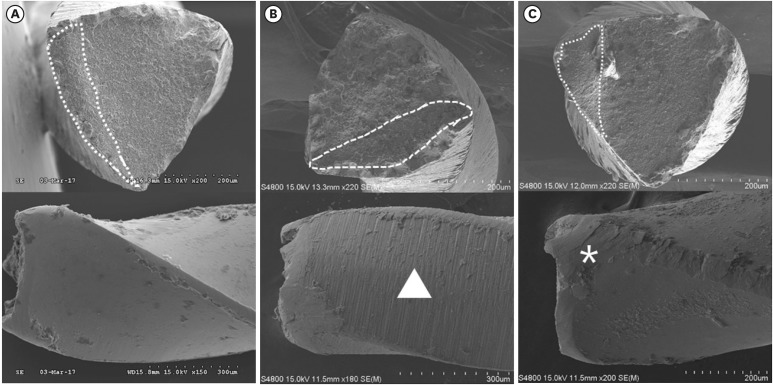

Figure 3

Torsional and cyclic fatigue resistance of the tested NiTi files

| Group | Torsional resistance | Cyclic fatigue resistance | |||

|---|---|---|---|---|---|

| Fracture angle (°) | Ultimate strength (N·cm) | Toughness (N·cm°) | NCF | Fragment length (mm) | |

| DPT | 511 ± 60a | 2.89 ± 0.38b | 1,140 ± 147b | 1,134 ± 246b | 2.91 ± 0.41 |

| PTU | 543 ± 57a,b | 3.08 ± 0.38b | 1,333 ± 183c | 842 ± 59a | 2.53 ± 0.53 |

| G6 | 594 ± 90b | 2.13 ± 0.13a | 974 ± 148a | 944 ± 123a | 2.96 ± 1.51 |

NiTi, nickel-titanium; NCF, number of cycles to failure; DPT, Dia-PT NiTi file system (Dia-Dent, Cheongwon, Korea); PTU, ProTaper Universal NiTi file system (Dentsply Maillefer, Ballaigues, Switzerland); G6, G6 NiTi file system (Global Top Inc., Goyang, Korea).

a,b,cDifferent superscripts indicate significant differences between groups (p < 0.05).

NiTi, nickel-titanium; NCF, number of cycles to failure; DPT, Dia-PT NiTi file system (Dia-Dent, Cheongwon, Korea); PTU, ProTaper Universal NiTi file system (Dentsply Maillefer, Ballaigues, Switzerland); G6, G6 NiTi file system (Global Top Inc., Goyang, Korea).

a,b,cDifferent superscripts indicate significant differences between groups (

KACD

KACD

ePub Link

ePub Link Cite

Cite